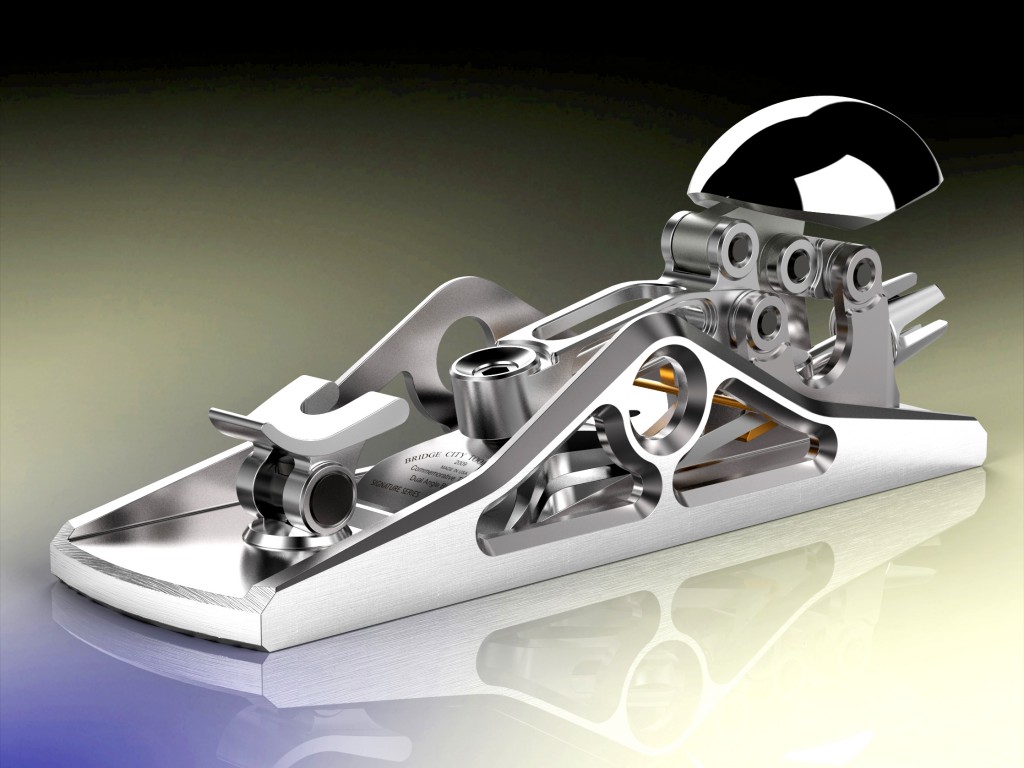

As promised last week, here are further specs on the CT-17 Dual Angle Block Plane;

Weight: 748 grams/1.65 lbs

Overall Height in Use: 61.2 mm/2.41 inches

Sole Length: 162.5 mm/6.4 inches

Sole Width: 48.75 mm/1.92 inches

Iron Width: 34.92 mm/1.375 inches

Iron Finish: Back, Optical Lap < 4 RMS

Iron Thickness: 4 mm/.16 inch

Iron Material; A2 Tool Steel, Rc 60-62, Cryo treated

Iron Bevels: Low Angle: 30 Degrees (25 primary +5 deg. micro bevel), Regular: 35 Degrees (30 primary +5 deg. micro bevel)

Iron Tension: Adjustable

Depth of Cut, Change per Revolution: .025mm/.001 inch

Throat Opening Range: 0 – 4 mm/.15 inches

Maximum Blade Cant : 2.5 Degrees

Sides to Sole Squareness: plus/minus .05mm/.002 inch

Materials: 304 Stainless, Steel Pivots

Blade Guard: Anodized Aluminum, Resides in Plane during use, attaches to back edge of iron for sharpening (affixed via 2 rare earth magnets)

Finish: Interior of body & components; glass bead finish, sides abrasively grained, pivots black oxide. Cap is polished. There is no black chrome on this piece.

Traditionally, most metal block planes use a cross-pin to anchor the chip breaker/cap to the body which holds the iron in place. By eliminating this pin, we were able to address the ergonomics of the tool with new light. The pic below, utilizes one of the stereo lithography models to illustrate the hand position where the index finger rests directly behind and above the cutting edge in a contoured pocket–this I am excited about because it feels great;

The design of the body is “circle centric” as circles were the predominate theme in the tool–they are everywhere and accentuated when possible to reinforce the theme. As illustrated below, the main holes in the body make grasping the tool securely easy and without much effort–it feels like it belongs in the hand…

The pic below illustrates the most traditional hand position using a block plane;

Although not illustrated here, the front “tote” pivots for two hand use and the inclination can be adjusted to suit your tastes.

For the past couple of years I have been wallowing in the money pit of radio controlled helicopters–while on my work retreat I realized they have had quite a subtle influence in my work over the past year or so. With the CT-17, I consciously used the influence as a design criteria as you can see below…

Regarding the clues in this totally awesome and worthless blog;

Clue # 1 was a close-up/abstract of the “tail pipe” depth adjuster.

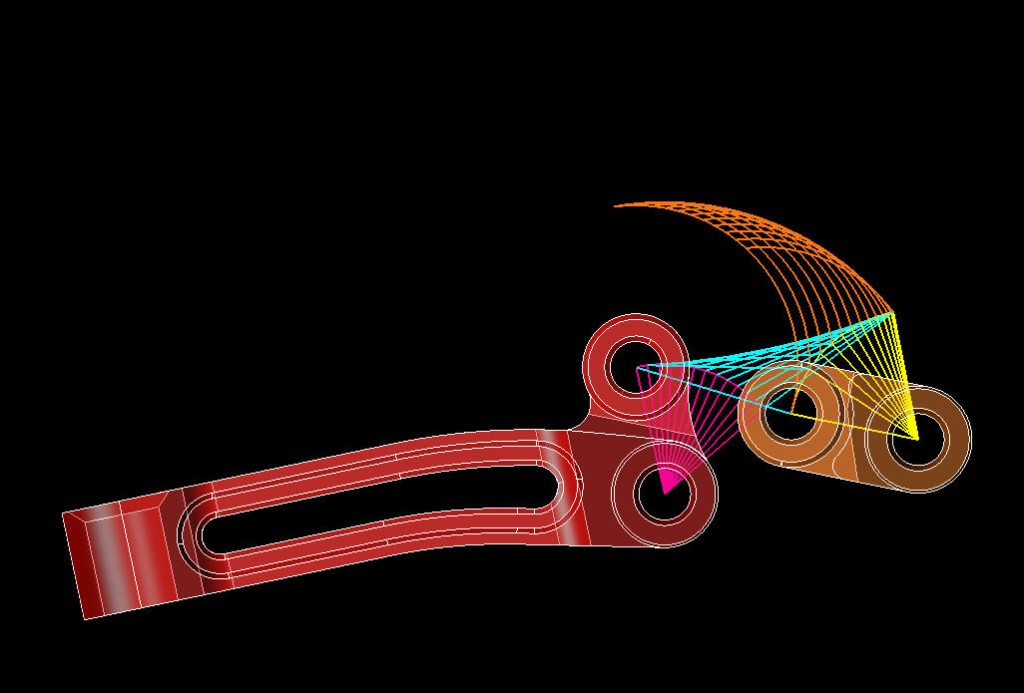

Clue # 2 involved the making of the video. The blade lock mechanism is not linear and at thirty frames per second, I needed to know the exact location of the clamp arm, cap and link throughout the range of motion when opening and closing. This involved a sequence of 12 individual frames to open and 12 to close–the animation software we use is not constraint or interference based so I had to do it manually. This illustration below should bring clarity…

The rest of the clues should make sense now.

Regarding the video, it was put together by Michael who also wrote the music beat. Editing by yours truly, hosted by YouTube. You are probably thinking, I would love to see that again! Here ya go;

For those of you curious about the software we used in this project (not in any particular order); Cobalt, SharkFX, HyperShot, HyperMove, Premier Pro, PhotoShop, Excel and FantaMorph.

On a personal note, I have been deeply troubled by the story of Phoebe Prince (the Massachusetts high school freshman who took her own life after relentless bullying by classmates). Why, we as a culture allow this kind of thing to happen is beyond my ability to comprehend. I was once told that bad people exist because good people do nothing.

So, on a much less serious scale–completely insignificant in comparison–but nevertheless related, we here at Bridge City deeply appreciate those of you who take the time to correct some of the inaccuracies and mean spirited posts circulating on the internet regarding this tool. It is a huge step in making the internet a much more useful tool.

More questions regarding the CT-17? You know where to find me.

Thanks to all for making this project so much fun. For those of you who earned a $50 Gift Certificate, you can expect an email sometime in the next 10 days–Natasha, aka. “The Gift Certificate Queen” is on vacation this week.

–John

New Tools

Newly engineered woodworking tools at Bridge City Tool Works

CT-17 First Peek…

April, 15th, 2010

I want to thank all of you crazy people for participating in the CT-17 guessing game–although nobody won the $100,000,000,000 prize, EVERYBODY who contributed to this thread (up until noon 4/15) has a $50 Gift Certificate coming–I thought this was fun. AND, I have at least two new ideas to pursue!

Should we do this again next year? What if I bumped first prize up to $100,000,000,000,000?

Oh, I almost forgot; here’s a little clip of the CT-17…our website/store will be updated later today.

Thanks again-for making this all possible.

Now I get to go home and do my taxes. I know I am not getting a refund but we are hoping you do!

–John

The Tool Too Sexy For Mass Production–R Rated!

December, 13th, 2009

Something about this tool awakens prurient interests…at least mine anyway–I feel just like I did approximately 50 years ago when a band of misguided 10 year olds found their first Playboy magazine at the local illegal dumping site…

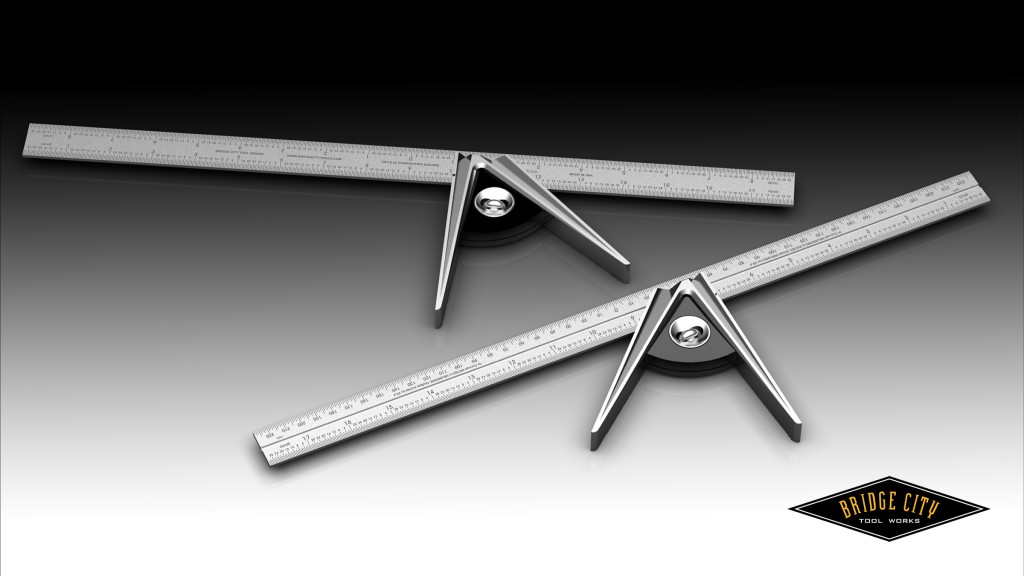

We have been playing with the prototypes here for a couple of months and this tool is way cool. Study the pic below because we have made a beneficial change to the 18″ blade we think you will really like.

Here’s what is different; the 18″ blade is unique and has some new functionality that will save you time. The bottom scale is in inches (32nd’s) and regardless of what hand you hold the square in, you can set the long leg to whatever distance you desire from the end of the blade.

The top scale features centering rules on each face, one metric and the other imperial. I would not use the imperial centering rule for finding centers, I would use this scale with straight leg aligned on 9″ (zero on the center scale) and as such, converts the square to a killer hook rule–reads from the leg out as opposed to the end of the blade in.

Opposite of the imperial centering scale is the metric (.5mm) centering scale which reads either left or right from the center. This is what I would use to find centers, i.e., 42.5 on the left and 42.5 on the right and you know center. This is way easier than reading 2-23/32″ on the right and 2-23/32″ on the left.

In addition, for those of you who are trying your best to wean yourself from the lunacy of imperial measurements, with the long leg set to 9″ on the lower scale, you can use the top scales to quickly convert between imperial and metric. This is cooler than you think.

We are also including in the kit a standard 12″ blade, all imperial because, hey this is America damit! (Not my view, but we need to pay rent here…)

Milled from solid stainless steel and graced with a black chrome web, this is the next tool in our Bridge City Essentials series. We will begin accepting pre-production orders as soon as we quantify our costs in a couple of days.

Now, I don’t have a tree-house anymore, but IF I DID, this tool would join Ms. June, 1963 as one of my most cherished belongings.

Your thoughts?

–John

Bridge City Essentials; Black Chrome and Stainless Marking Gage

September, 16th, 2009

As we continue to celebrate our 25th anniversary I am pleased to give you a peek into what is coming next.

Sometime in the next day or so, we will be announcing the pre-production run of the next Bridge City Essential–an updated version of our MG-4 Marking Gage and calling it the MG-5. Stainless steel, black chrome…OK, I will fess up–this black chrome is the coolest stuff–I am hooked.

Frankly, the world does not need another marking gage but this one is notable because it has two “business ends” one, a beveled cutter for straight work and a scribe pin for following curves. It is small, fits the hand great and the black chrome just feels oh so sexy.

We are working on pricing but the MG-5 will be well under $150 so it won’t break the bank…hell, what I am thinking, all the banks are broken! Don’t know how many we are going to make yet and don’t know if we will make it again (We are in the anti-inventory business) so give it a ponder.

Here’s a Sneak Peek of the prototype;

–John

Special Limited Edition 25th Anniversary Plane

June, 17th, 2009

Last year when we introduced the CT-14 Shoulder Plane, we made a couple out of solid stainless steel with no intention of ever producing a stainless version–the machining costs are astronomical.

I have hauled one around with me at several of the Lie-Nielson Hand Tool Events and it is definitely a head-turner–works great too. Recently we had a customer who wanted to buy the plane and it was explained it was not for sale.

“Name your price.” he said. I have heard this before and it is hard to ignore.

We held our ground. Until last week.

In a staff meeting it was suggested that we make a very small run of these and include them as part of our 25th Anniversary celebration. What is a small run? 50.

Each of these planes will be hand signed and serial numbered. Delivery will be in October, the price; $2500.

If this interests you, give us a call (1-800-253-3332). As of this writing there are 17 remaining. Phone orders only–serial number will be assigned at time of order.

If you are looking for a something that is truly unique, perhaps a great investment, this may be worth considering. There is nothing like it.

Did I mention I have developed a tool fetish for stainless steel? This stuff is awesome!

–John

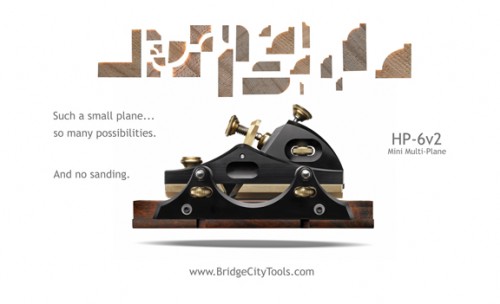

Sneak Peek at Two New HP6v2 Kits….

April, 7th, 2009

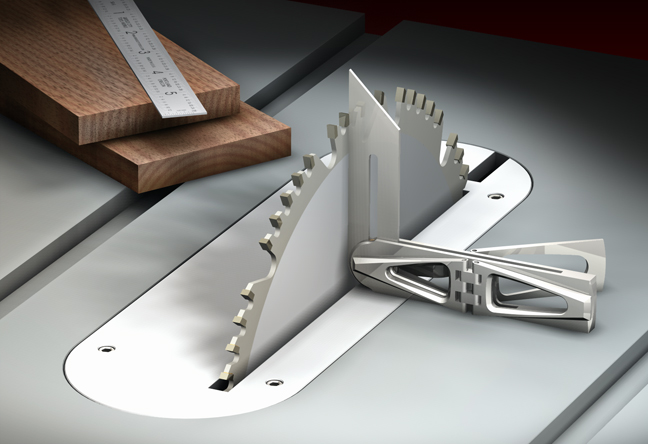

The video below shows our new surface cove kits (should be available next week). Auto orders have been shipped.

This profile is really interesting. Not only does it do what it is designed to do, which is create a surface profile wherever you choose, but when used in conjunction with the miter fence, it is also a small rabbet plane, and creates two unique molding profiles depending on when you stop cutting. (We included a stop motion clip to illustrates how this works.) This profile would make cool tambours and adds a rich detail to a myriad of projects. It also cannot be replicated with a router. Check your inbox next week for the introductory special.

We finished shooting video of our next “Silent Woodworking” invention and I think you will find this to be an amazing new tool. Hopefully we will have pricing done next week as well.

And, I just finished the design of Commemorative Tool #16!

I think I need a break…

John

Next Week We’ll be in Berea, KY: Woodworking in America

November, 6th, 2008

In preparation for the upcoming Woodworking in America conference, I decided to make a display featuring all of the cuts possible with our HP-6v2 Mini-Multi plane. This turned out to be quite fun and, enlightening.

Every week my fondness for working without noise grows–this little display project was done in our front office on the workbench in our modest showroom. I was so happy with my mess I deemed it noteworthy. See pic below.

While making the different cuts (about 60 two foot strips) it became apparent to me that these samples are a great way to play. I was goofing off, combining different moldings together and I felt like a kid playing with Lego pieces. It was really interesting and a great way to discover new, distinctive forms. When Michael and I get back from WIA, we are going to produce a video on this very activity.

Now for something completely different:

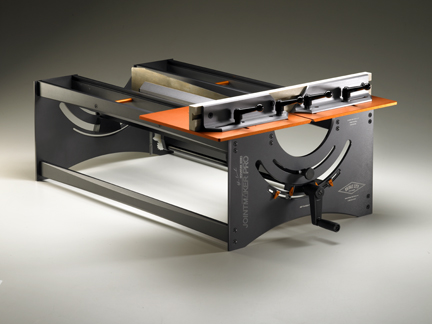

The Jointmaker Pro was recently named one of the best new products of 2008 by Popular Woodworking.

Everybody is working their tail off on the initial run and we will hopefully ship before the holidays.This is a big job! We have about 20 units remaining in this run and then we will begin a wait list for run #2. We hope to sell the remaining units at the Woodworking in America Conference–we’ll see…

Commemorative Tool #15, will begin shipping within the next two weeks! Tomorrow I will have a first article for final inspection! This is exciting.

The NEW and IMPROVED CenterScribe will ship in the next week or so as well!

The original CenterScribe was one of the top 5 tools we ever produced. This one is much better! Holds a pencil in addition to the scribe, finds centers on dowel ends, rectangular or square stock and has ZERO backlash, and will cost less!

That’s all for now.

Oh wait! Did I mention that I am working on Commemorative Tool #16?

–John

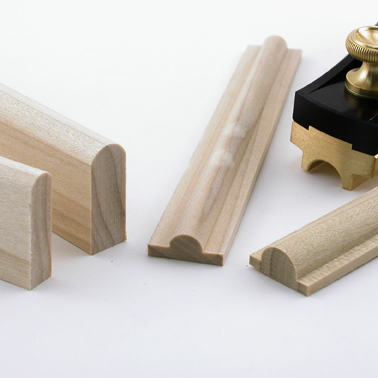

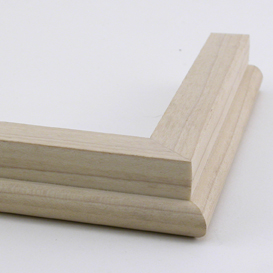

Cool New HP6v2 Profiles!

November, 4th, 2008

The sole/iron kits we are introducing this week for the HP6v2 Mini Multi-Plane may be the most versatile in the family. The pictures below tell most of the story…

These options allow you to cut a half bead on an edge or a 3/4 bead on a corner. In addition, either will do a full bull nose on either 1/2″ or 3/8″ thick stock.

The results are razor crisp. This detail is used in moldings, box making, frames, drawer details and a host of other projects when a sudden urge to deviate from 90 degree corners comes upon you…

Here you can see a full 1/2 bead and a 3/4 bead. The 3/4 bead will be fully exposed once I cut the cheeks off.

This image shows how the bead is formed on adjacent faces. Using the fence is a must for this profile.

Here you can see half beads and bull nose cuts. This is a great addition to your shop if you make boxes or frames.

I don’t know about you, but I get excited to add form and texture to my designs, and I really get excited when it can be done without sanding!

The 3/4 bead is an awesome detail not easily replicable with a screaming router. This is the same piece of wood in the first image after the bead was completely liberated with a shoulder plane. It is a rich detail.

Here is the same miter joint from the opposite face. I don’t think we have an HP6v2 profile with as many different options from the same sole/iron kit as these two new face bead kits.

These have not been posted to our website as of this writing, but they are in stock and you should be able to order them before the end of this week.

–John

The CT-15 is Coming Together!

October, 9th, 2008

The best part of my job is when components of a new tool arrive for first article inspection–and in this case it is really a big deal because the parts on my desk today are for Commemorative Tool #15, our limited edition multi-square.

As mentioned earlier, I have developed a fetish for stainless steel. It is tough, durable and likely will not rust (all stainless steels will rust under the right conditions–as dumb as that sounds.)

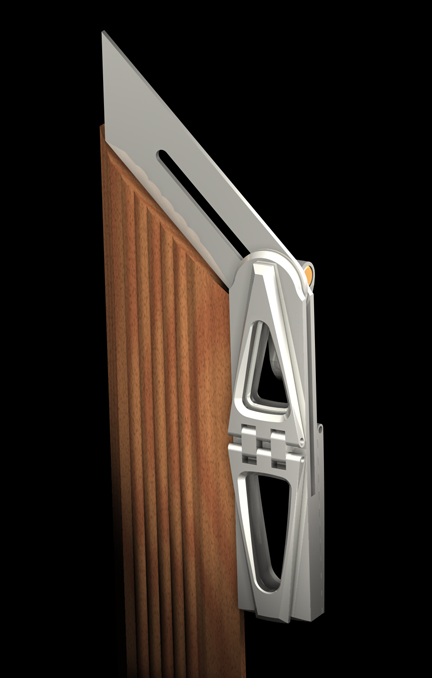

Over the past couple of weeks we have been testing various bead-blasted finishes and have settled on a matte finish that feels just plain sexy. Below are a couple of pics of some parts–the t-bevel lock lever/pocket clip is really cool.

–John

PS: I have actually gone two days in a row without making Squiggle Wood. I think I need help.

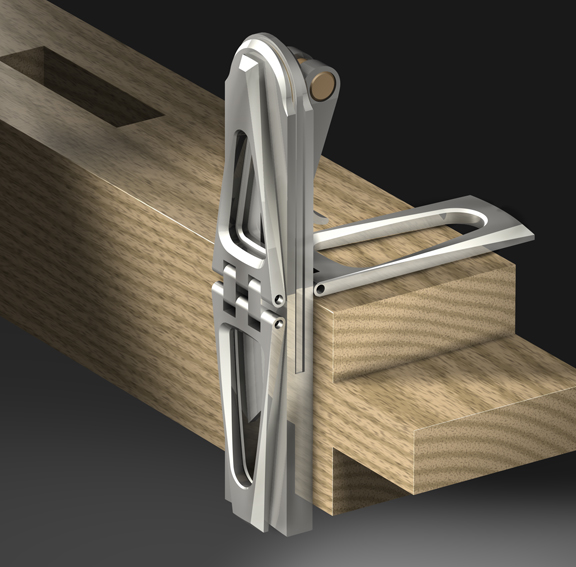

The image above is a computer rendering of the CT-15 Multi-Square, it is five layout tools that fit in your apron pocket.

The finish and form of this cam lock/clip is really cool!

When this tool is completely assembled it is really going to be fun to use.

News from the Sticks and Stones Will Break Bones but Words are Worse department: We used Michael as a hand model because I was informed by my staff that my hands are not as photogenic as my knees or elbows.

Commemorative Tool #15; The Back Story

September, 3rd, 2008

Each year I get to pull out the stops and create a tool we pledge to never make again. The introduction is the highlight of our year and I am pleased to offer a sneak peek to those that follow this blog.

This year I had three choices for the 2007 Commemorative Tool and picked the one that interested me the most. In addition, I am going through a stainless steel phetish (that is a cross between phase and fetish–works for me since I made it up…) after a 25 year romance with brass. This tool sings in stainless steel.

What if you could carry all of your layout tools in the breast pocket of your apron?

The pics are self-explanatory. Prices and availability will be posted on our website sometime next week. (Under $300 and will be available by the holidays).

Guess I better start on the 2008 Commemorative Tool…

–John

PS: Let me know what you think!

This is the CT-15 Multi-Square and consists of a 90 degree Saddle Square, 8:1 Dovetail Square, 6:1 Dovetail Square and the tightest locking T-Bevel you have ever owned. Cam lock also serves as a pocket clip. I spent over a month working on the lines of this tool. The variable length chamfers are an elegant functional detail (pocket friendly) that not only invites use, but is food for the eyes.

We invented the Saddle Square years ago and this one is our best. Adjacent lines are perfect–used here for a tenon on 8/4 stock.

The layout of dovetails is fast and accurate with either of the two dovetail squares built into the CT-15 Multi-Square.

Using the CT-15 as a try square is easy. Notice how the saddle square can be used as a kick stand–this is cool.

The tightening mechanism for the t-bevel is field adjustable and rock solid.

The CT-15 is just over 4″ in length and approximately 1/2″ thick. It is milled from solid stainless steel and is made like a fine pocket knife. We are only going to make this version this once.

Copyright 2008, Fine Tools, LLC All Rights Reserved.